東莞金坤新材料股份有限公司是一家集研發(fā)、生產(chǎn)、銷售為一體的稀土磁鐵制造及應(yīng)用方案服務(wù)商新三板上市企業(yè),擁有豐富的磁性材料行業(yè)研發(fā)、制造經(jīng)驗(yàn)和完整的供應(yīng)鏈體系,工廠位于東莞市道滘鎮(zhèn)小河工業(yè)區(qū),立足珠三角,服務(wù)全國和全世界客戶。

作為釹鐵硼磁鐵應(yīng)用技術(shù)專家,我們擁有先進(jìn)的磁性能分析儀器和經(jīng)驗(yàn)豐富的技術(shù)工程師,快速幫助客戶更好的選擇合適的磁性產(chǎn)品和整體應(yīng)用方案,也可根據(jù)客戶需求定制各種磁組件產(chǎn)品。我們從客戶產(chǎn)品開發(fā)階段就介入的售前服務(wù)模式,致力于為客戶縮短產(chǎn)品開發(fā)周期,降低開發(fā)成本,提高產(chǎn)品品質(zhì)。

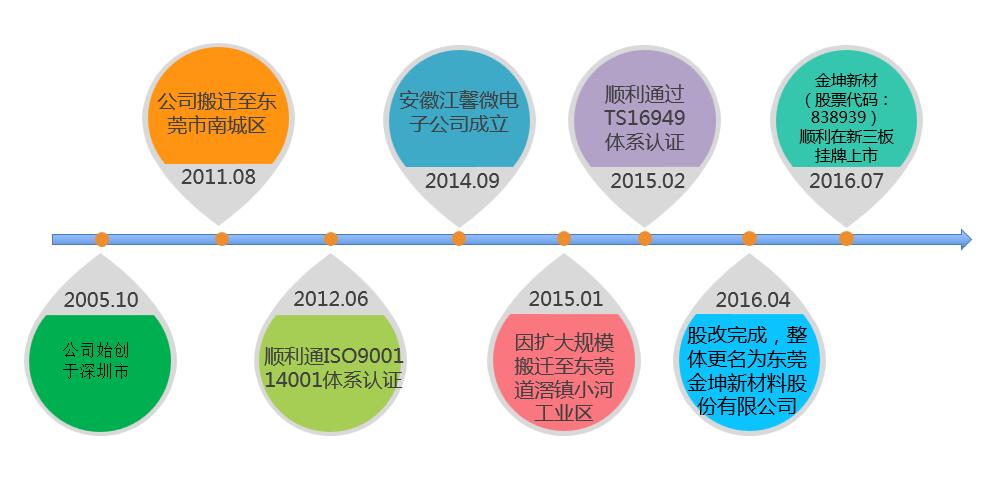

金坤磁鐵有限公司成立于2005年10月。經(jīng)過12年的卓越奮斗,現(xiàn)已成為集原材料、研發(fā)、生產(chǎn)質(zhì)造為一體的領(lǐng)軍級(jí)磁鐵企業(yè)。

公司現(xiàn)有三座工廠:內(nèi)蒙古包頭原材料工廠,專業(yè)生產(chǎn)磁鐵原材料;安徽江馨微電工廠,專業(yè)生產(chǎn)微電機(jī)用于手機(jī)攝像頭;東莞小河工廠是集研發(fā)精工為一體的綜合生產(chǎn)基地:廠區(qū)內(nèi)規(guī)劃辦公面積約1800余平米(獨(dú)棟辦公室),生產(chǎn)車間約5,600平米,員工宿舍約2,400平方米。 員工總?cè)藬?shù)約320人。現(xiàn)有切片設(shè)備為500余臺(tái),年產(chǎn)能15000 萬平方厘米(合約250噸)。

擁有多種異型磁鐵加工能力,設(shè)備有內(nèi)圓切割機(jī),打孔機(jī),線切割,單面磨床,雙面磨床,立式磨床等多達(dá)700余臺(tái),以滿足各個(gè)行業(yè)對(duì)磁鐵的生產(chǎn)要求。 廠內(nèi)有多種可靠性測(cè)試設(shè)備如鹽霧機(jī),恒溫恒濕機(jī),高溫測(cè)試機(jī),磁特性分析儀,二次元投影儀,跌落測(cè)試設(shè)備等各種設(shè)備以滿足產(chǎn)品特性需求。

金坤磁鐵生產(chǎn)的釹鐵硼永磁鐵廣泛應(yīng)用于、醫(yī)療、通訊、電子信息、新能源汽車、風(fēng)能發(fā)電、軍事國防等領(lǐng)域。公司已經(jīng)通過ISO9001,ISO14001,TS16949國際認(rèn)證體系。

金坤磁鐵與微軟、TCL、海信、比亞迪、佛山照明、SKULLCANDY、LITEON、昂碩電聲通訊等眾多行業(yè)企業(yè)是戰(zhàn)略合作伙伴!

東莞金坤新材料股份有限公司依托"世界制造業(yè)之都(東莞)"的產(chǎn)業(yè)群優(yōu)勢(shì)和技術(shù)優(yōu)勢(shì),不斷加大技術(shù)創(chuàng)新力度,不斷改進(jìn)燒結(jié)釹鐵硼磁鐵生產(chǎn)的工藝與設(shè)備,使高端產(chǎn)品質(zhì)量和性能得到了很大的提高,進(jìn)一步提高了企業(yè)的市場(chǎng)競(jìng)爭(zhēng)力;我司積累了成熟的高端產(chǎn)品制造和高效服務(wù)客戶的能力,致力3~5年成為行業(yè)高端、異型、精密型釹鐵硼磁鐵的領(lǐng)軍企業(yè)。

Jin Kun Magnet Co., Ltd. was established in October 2005. After 12 years of struggle for excellence, has now become a set of raw materials, research and development, production quality as one of the leading magnet enterprises.

The company has three factories: Inner Mongolia, Baotou magnetic raw materials factory, specializing in the production of magnet raw materials; Anhui Jiangxin micro-power plant, specializing in the production of micro-motor for mobile phone camera; Dongguan Creek factory is set research and development Seiko as an integrated production base: plant planning office Area of about 1,800 square meters (single-family office), production workshop of about 5,600 square meters, staff quarters of about 2,400 square meters. The total staff of about 320 people. Existing slicing equipment for more than 500 Taiwan, with an annual capacity of 150 million square centimeters (250 tons contract).

There are more than 700 sets of equipments, such as inner circle cutting machine, drilling machine, line cutting machine, single-side grinding machine, double-sided grinding machine and vertical grinding machine, to meet the production requirements of various industries. The factory has a variety of reliability testing equipment such as salt spray machine, constant temperature and humidity, high temperature testing machine, magnetic properties analyzer, the second element projector, drop test equipment and other equipment to meet product demand.

Jin Kun magnet NdFeB magnets are widely used in medical, communications, electronic information, new energy vehicles, wind power, military and defense and other fields. The company has passed ISO9001, ISO14001, TS16949 international certification system.

Jin Kun magnet and Microsoft, TCL, Hisense, BYD, Foshan Lighting, SKULLCANDY, LITEON, Angshuo electro-acoustic communications, and other industries and enterprises are strategic partners!

Jin Kun Magnet Co., Ltd. relies on the industrial cluster advantages and technical superiority of the "World Manufacturing Capital (Dongguan)", continuously intensifies technological innovation and continuously improves the production technology and equipment of sintered NdFeB magnets, Quality and performance has been greatly improved to further enhance the market competitiveness of enterprises; Division I has accumulated a mature high-end products manufacturing and efficient customer service capabilities to 3 to 5 years to become the industry high-end, shaped, precision NdFeB Boron magnet the leader.